Lessons from the Land: Scaling Traceability and Transparency in the Seafood Sector

Traceability within the seafood sector has become increasingly prevalent in recent decades because of the need to develop tools to combat illicit activities, improve fisheries management, and provide transparency to meet consumer demands. However, traceability and transparency are often used interchangeably, despite their difference in meanings. Traceability provides details and data of a product’s end-to-end path within its specific supply chain. In contrast, transparency is about companies and governments sharing accessible, truthful information with the public sector about the product’s journey, as well as the policies, commitments, and actions of those involved (Seafood Traceability Glossary, BSR). Full transparency is difficult to disclose without effective traceable methods in place. Knowledge of one’s supply chain is the backbone of traceability, and without the mapping and management of supply chains, end buyers cannot attain transparency of a product’s source.

Despite the apparent reasons contributing to seafood exceptionalism, such as the vast geographical boundaries within oceans that challenge governance and oversight, the seafood sector operates a similar global, dynamic supply chain map compared to such commodities as cotton, cocoa, palm oil, and minerals. The question is, what can the seafood sector learn from these other globally traded commodities to achieve successful traceability and transparency from bait to plate?

Technologically Advanced Traceability

Traceability is needed to achieve supply chain visibility. Although traceability isn’t necessarily a new development for supply chain management, electronic traceability is fast emerging. As an increasingly widespread population demands to know a product’s origin, technological developments are unfolding to aid in tracking products, further combating mislabelling of goods, and improving data quality and quantity.

Companies must consider all stages of the supply chain that form the end-to-end chain and network. In doing so, insights can be gained to improve the performance of supply chain operations. Identifying areas for improvement and addressing them can impact the efficiency and data quality in the entire supply chain. Blockchain technology can provide insight into the chain and network by enabling companies to record events or transactions within a supply chain that are unalterable. This information is then shared in a secure, transparent, and efficient manner to those in the network, providing a trustworthy source of information. Blockchain is now widely used across the cotton, cocoa, palm oil, and mineral sectors, and has been tried and tested within the seafood sector.

In addition to blockchain technology, DNA tracing and ‘bag and tag’ (also known as a ‘field tag’), have been adopted to verify data using genetics to identify raw and processed products. In recent years, DNA barcoding has become a universal tool for traceability. It has proved to be a fast, reliable, and cost-effective solution to tracking and detecting the authenticity of products derived from raw materials.

Traceability originated as a tool for tracking products for food safety but has now grown to address environmental and social sustainability. With the development of traceability technology and methods like blockchain and DNA tracing, trust can be built between consumers, retailers, and suppliers. There can be challenges incentivizing the use of novel traceability tools, but industry coordination and government action have been shown to accelerate traceability investments.

Incentivizing and Accelerating Traceability

Supply chain collaboration

The network of individuals within supply chains often makes it challenging to achieve equitable solutions for all stakeholders involved, highlighting the need for supply chain collaboration. By developing communication tools and considering the needs of those harvesting, processing, and supplying goods to consumers, companies are more likely to adopt efficient and successful traceability methods that can increase profitability and transparency. Overall, collaboration provides a way for the supply chain network to address challenges, share knowledge, harmonize data requirements (standardization), and develop interoperability within traceability systems. A lack of standardization and interoperability may hinder the effectiveness and quality of the traceability system. With this in mind, companies come together to improve traceability in their supply chains to manage legality better, mitigate risk, and address issues when they arise.

Governance

Strong governance on national and international scales has proven effective in incentivizing traceable supply chains. Governing bodies with the sole purpose of enhancing traceability and sustainability across commodities puts pressure on every aspect of the supply chain, which requires more effective coordination amongst those within the supply chain. Implementing governance throughout supply chains may strengthen enforcement and expand partnerships between state and local governments. New legislation has the power to accelerate industry to improve full chain traceability. However, top-down regulation strategies can result in slow industry compliance and limit their effectiveness without enforcement or oversight. Governance in combination with industry collaboration will contribute towards full chain traceability, facilitating the development of equitable solutions.

Translating Traceability to Transparency

The role of businesses

Understanding the difference between transparency and traceability is important when creating supply chain management strategies to collect and communicate information accurately. Transparency helps to provide visibility via honest and factual communication within supply chains, leveraging traceability as a tool to provide accurate data and information on products.

Companies that prioritize transparency commit to supply chain engagement and publicly reporting on sustainability progress. Downstream actors refer to the companies involved with distributing and delivering goods to the consumers. Consumer awareness and highly publicized labor and environmental abuses increase the demand to know a product’s origin. In turn, these downstream actors are in a unique position to drive traceability improvements within their supply chains and improve transparency to meet consumer needs and regulatory compliance. With this business dynamic, brands pressure upstream actors to meet the evolving demands placed on those downstream.

Traceability provides key data of purchased products or ingredients for consumer-facing brands, enabling informed sourcing decisions and building a narrative for consumers. With consumer education and the demand for transparency on the rise, consumer demands are forcing companies to raise standards, which drives brands and retailers to prioritize traceability within the supply chains of products they are sourcing and selling.

As transparency becomes increasingly essential, corporate social responsibility and due diligence within supply chain management are needed. The exploitation of workers and data fraud can be unreported. However, with strong due diligence measures in place, the chain of custody can be monitored and managed to mitigate risks of human rights abuses within supply chains. These policies create a framework holding companies accountable to legal compliance, recruitment, and decent working conditions for workers in their supply chains. Transportation routes and points of trade act as the stepping stones throughout supply chains to enforce due diligence measures and address labor rights. Incorporating due diligence alongside electronic traceability methods, such as blockchain, has become increasingly helpful to meet environmental sustainability and social responsibility needs.

The role of third-party organizations

Third-party organizations, or those acting outside of the supply chain businesses, can improve traceability and transparency through such tools as certifications, audits, and education. The most effective organizations use training platforms, guidance documents, and data collection or surveys to support sustainability and labor rights. Specifically, programs aimed at educating employees and/or raising their awareness of human and labor rights produce the most measurable results and lead to the most improvement.

These certifications rely on traceability, or demonstrated chain of custody, and can aid in combating illegal products from entering the market if audited. Companies are advised to build audits into their due diligence plans, and can conduct these audits either in-house or by third-party organizations. Audits help surface problem areas within supply chains, such as gaps in traceability data or weaknesses in workplace safety compliance. Traditionally, internal traceability has relied on paper based one-up, one-down product tracking (the capturing of information from one trading partner below a company, and one trading partner above), providing information for inventory or health safety compliance. This style of traceability hinders end-to-end traceability and verification of a product’s full journey. The agreed-upon chain of custody standards created by third-party organizations provide helpful frameworks for businesses to use and assist in traceability data verification.

Conclusion

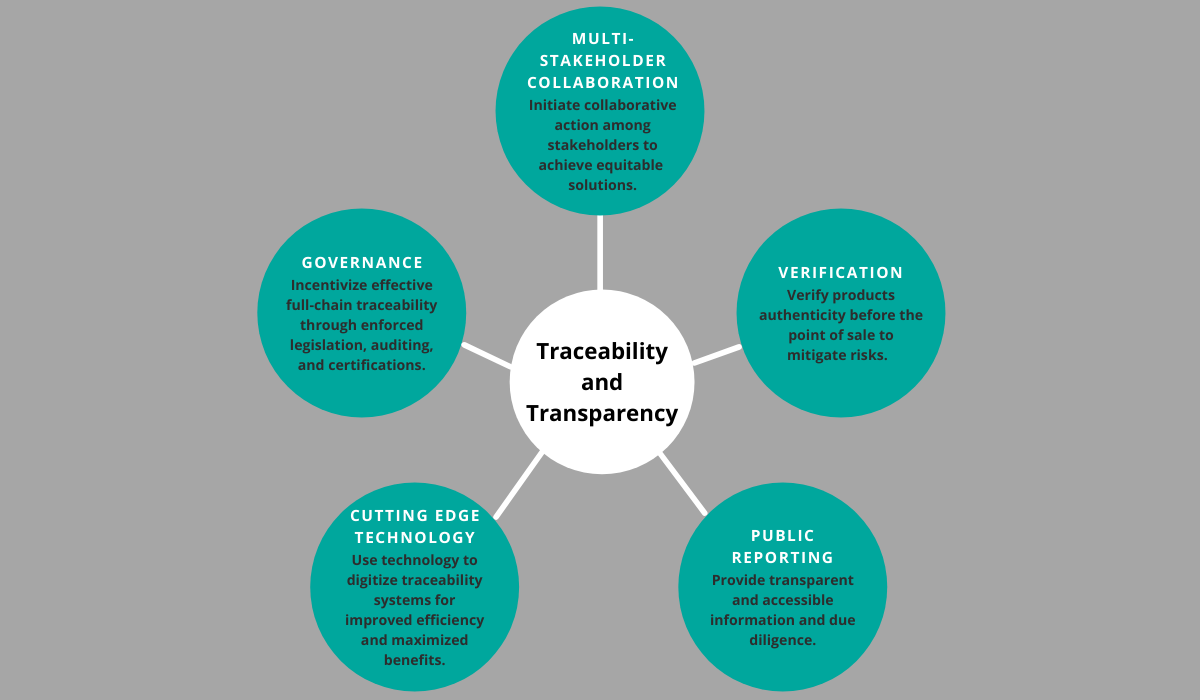

Developing innovative methods to achieve full chain traceability within global, complex supply chains can be challenging enough. Furthermore, scaling up potential traceability methods is a common challenge across sectors. Creating interoperable traceability systems that can share information across the supply chain is critical to achieving a broader adoption of traceability and transparency within the the full chain. Interestingly, many of the solutions and challenges discovered from other sectors are not unique and similar to those the seafood sector faces. The Comprehensive Traceability Principles outline many of these themes to improve traceability within the seafood sector, but some principles like interoperability, verification, and collaboration are universal. Maybe seafood exceptionalism is not as siloed as we once thought. Nevertheless, there are opportunities for the seafood industry to learn from these other global commodities about expanding traceability on a mass scale, identifying and managing both the risks in supply chains, and risks associated with mislabelling seafood:

- Cutting-edge tools such as electronic monitoring, blockchain, and DNA tracking have proved successful in providing traceability throughout commodities and are fast emerging within seafood supply chains.

- Multi-stakeholder collaboration builds trust and understanding about traceability needs and expectations, which will assist in selecting the most appropriate traceability tool and increasing return on investment. Additionally, this collaboration creates an opportunity to improve social responsibility and equity within supply chain business practices.

- Government action, both national and international, has shown to be effective in incentivizing and accelerating the necessity of traceability in global supply chains.

- Public Reporting is crucial for businesses and governments to improve transparency. Companies must understand their roles in implementing traceability and commitment to transparency through due diligence plans that mitigate risks within their supply chains.

- Verification of products is key to mitigate legal risks within supply chains and is more robust as traceability data quality progresses. Third-party organizations can assist in audits and help identify areas for traceability improvements.

There is great value in traceability software, yet the demand for interoperability within the seafood sector is currently lagging, leading to challenges with the scalability of seafood traceability. There is no single solution to achieve seafood traceability. However, scaling up interoperability within seafood supply chains is key to achieving full chain traceability. The good news is that efforts to excel interoperability have already begun. It simply needs expanding.